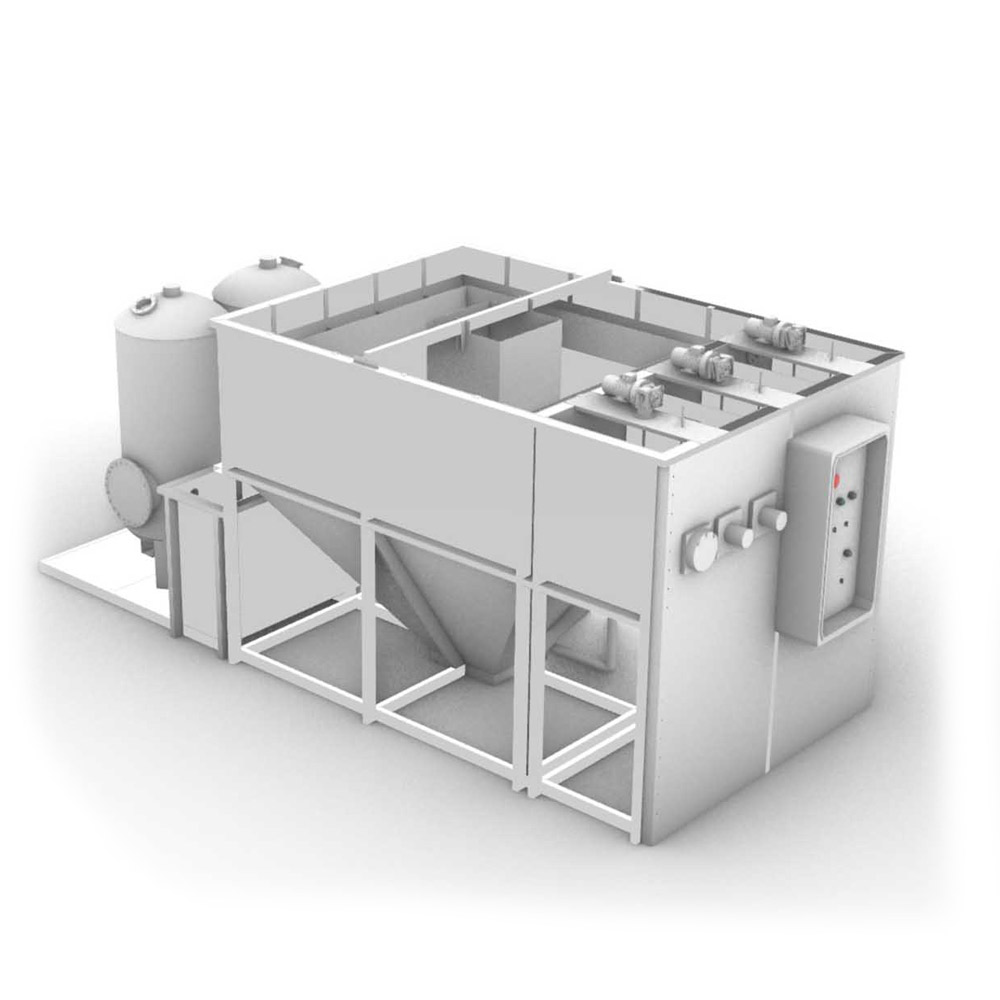

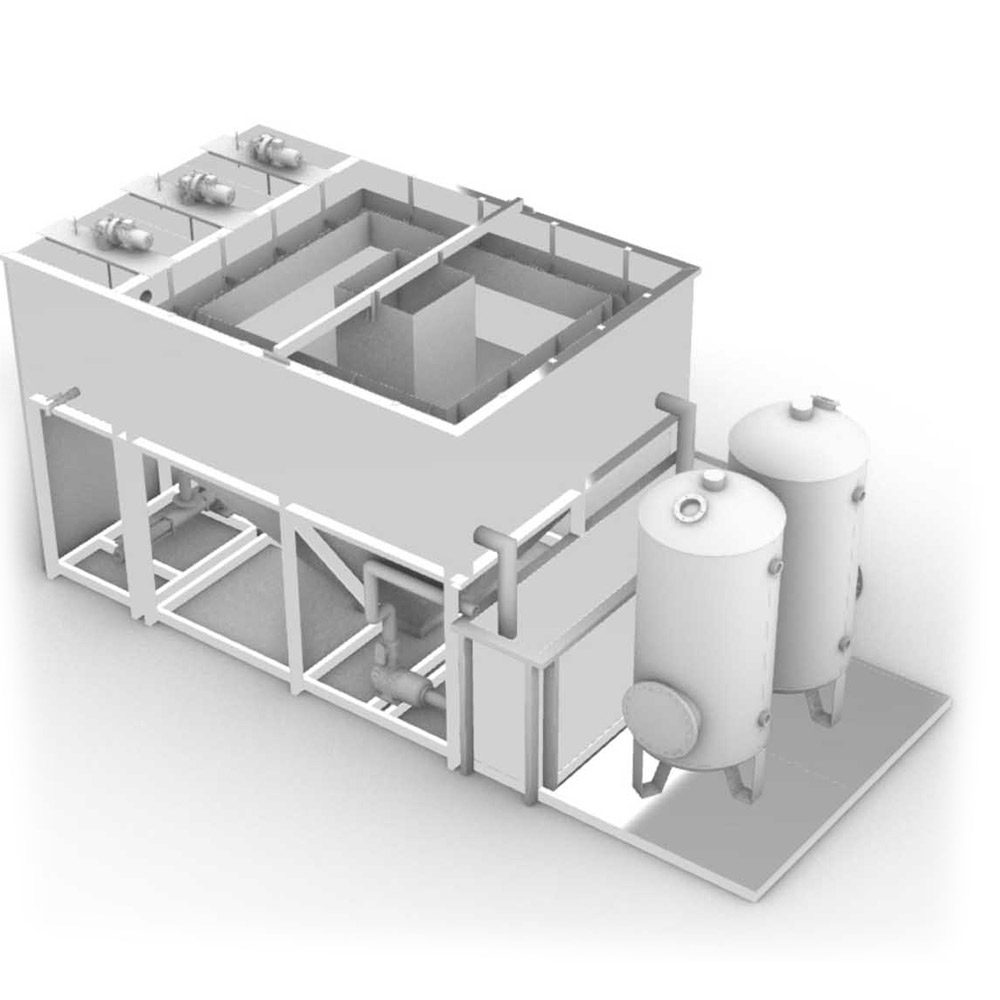

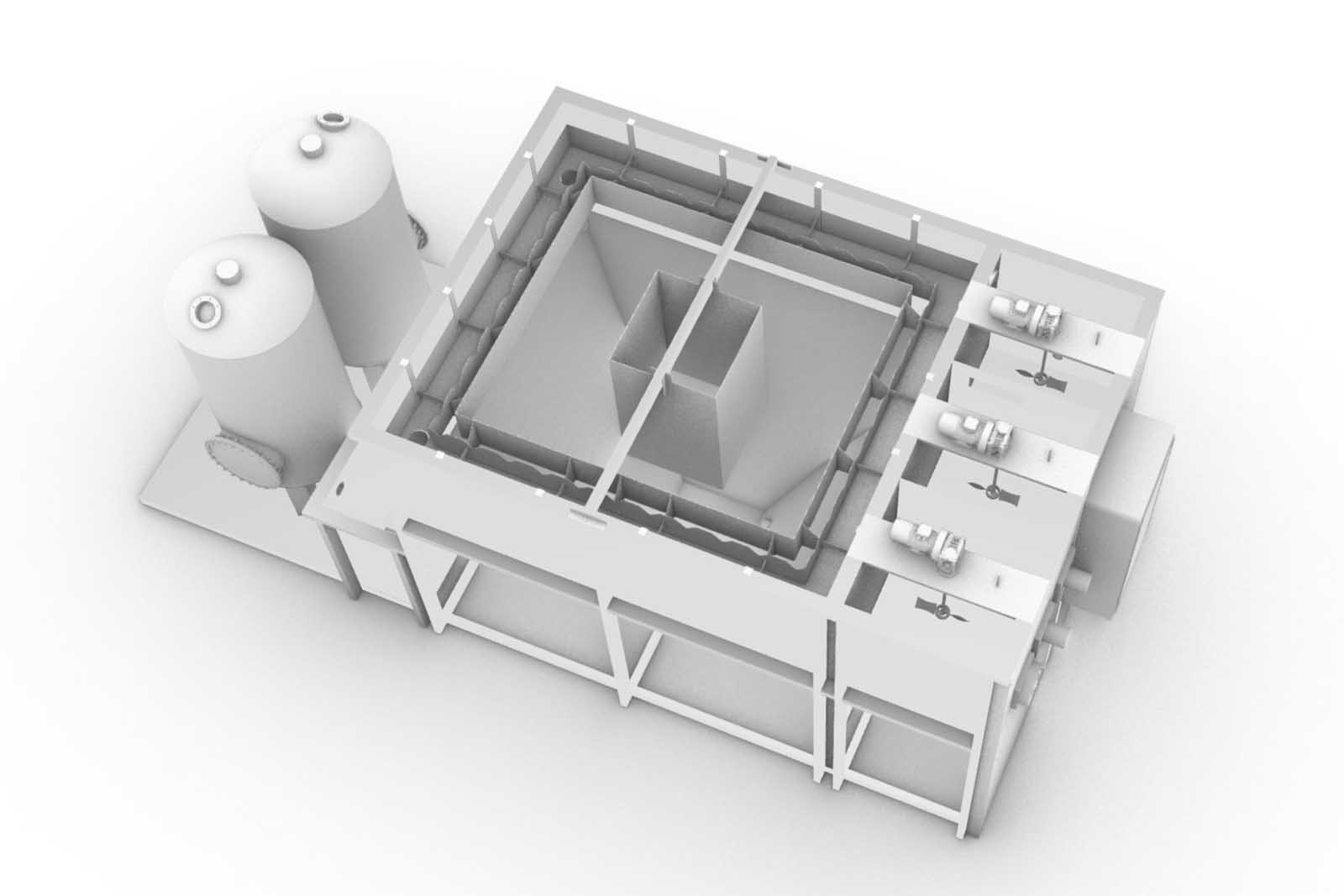

Chemical-Physical Treatment Plant

Usage Function

Chemical-physical treatment plants are designed to remove pollutants from water, typically poorly biodegradable substances, through the use of chemical additives. The plant utilizes a chemical-physical process where specific chemical products (flocculants) are used to promote the sedimentation process of solids present in water used in car washes, mechanical workshops, laundries, dyeing plants, etc.

Sand filter

Agitator unit

Construction Features

The plant is constructed in a monoblock with a reinforced PVC process tank. It is installed above ground and equipped with an upper inspection point with an external ladder. The control panel is integrated into the plant and equipped with a PLC (Programmable Logic Controller) for managing the entire purification system, including influent pump, chemical dosing, and flocculant agitation and mixing.

The raw sewage, after initial storage and accumulation, is vigorously mixed with one or more chemical reagents using three mixers. The colloidal particles, in stable suspension, are destabilized by the added chemical reagents, resulting in rapid coagulation upon contact with the chemicals. The result of coagulation-flocculation is the transformation of non-settleable colloidal substances into settleable substances, which can be easily collected in a subsequent sedimentation phase in the sedimentation tank or compartment as sludge.

Any excess sludge produced is optionally stabilized biologically or chemically and then sent for dewatering and final disposal.

The monoblock contains all the necessary compartments for effluent treatment, built with access to the top for inspection, and is equipped with a zinc-coated steel grid cover and an inspection ladder.

Advantages

- Operational flexibility in terms of purification capacity, with no significant decrease in purification efficiency in case of increased flow rates and/or pollutant loads.

- Simplified management.

- Reduced installation footprint.

- Easy removal and relocation to another site.

- The possibility of expansion by adding one or more modules.

Options

Depending on specific needs and requests, different types of treatment can be carried out on each plant, such as:

- Internal and external galvanizing.

- Internal enamel and external painting.

Internal epoxy alimentary and external painting

Accessories

- Electrical control panel.

- Mixers for mixing in the initial phase.

- Dosing pumps for chemical product dosing.