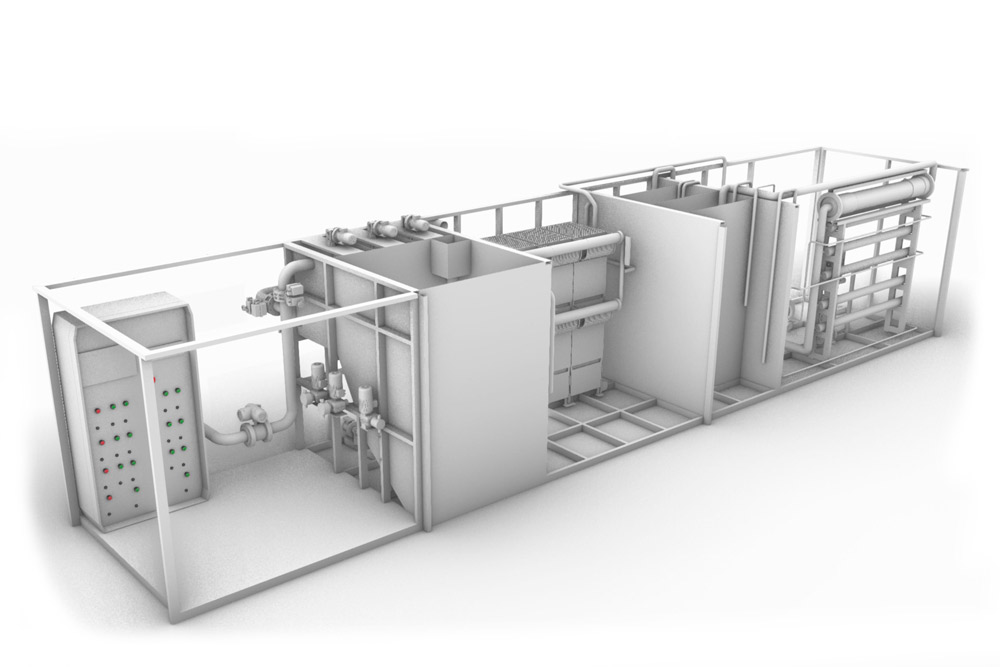

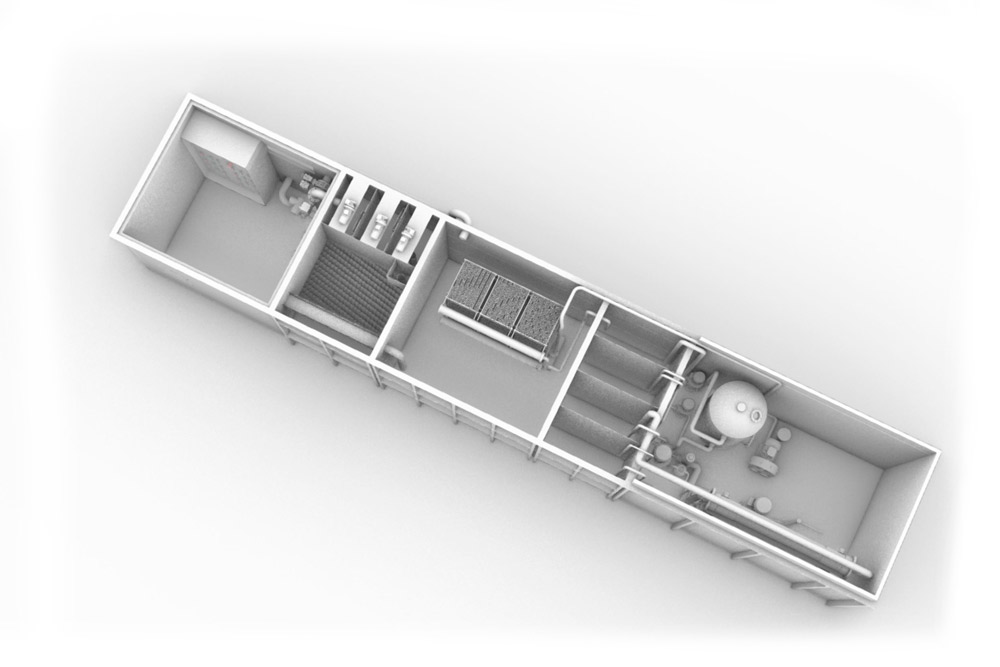

Leachate Treatment Plant

Usage Function:

Wastewater leachate treatment plants are used in the purification of landfill leachate, which is highly polluting, through a series of different stages housed in a single monoblock plant structure. The treatment consists of:

- Chemical-Physical Treatment: Three dosing pumps, equipped with mixers, are used for aluminum polychloride, caustic soda, and polyelectrolyte present in each reference tank.

- Sedimentation via Lamellar Packs: Sedimentation is achieved through lamellar packs.

- MBR Treatment: MBR (Membrane Bio-Reactor) treatment involves six specialized EBOX MBR modules with membrane cassettes, a metal frame, and medium bubble tube diffusers. The MBR system combines traditional activated sludge treatment with a membrane separation system. Active biomass is separated from the purified effluent using membranes instead of sedimentation, which is often the weak point of an activated sludge treatment plant.

- Activated Carbon Filtration: Activated carbon is an ideal material for the adsorption of various types of pollutants dissolved in water, such as mineral oils, surfactants, hydrocarbons, and substances insoluble in water.

- Ultrafiltration and Nanofiltration: Designed, sized, and built with high-quality procedures tailored to the specific needs of the client.

- Reverse Osmosis: Reverse osmosis treatment.

- UV Disinfection: UV disinfection treatment is highly effective and does not affect the taste or odor of the treated water. It is not particularly energy-consuming, does not require the handling or monitoring of hazardous chemicals, does not generate unwanted by-products, and is easy to install and maintain.

ByPass Solenoid Valve

Control panel

Construction Features

The plant is installed above ground and includes a technical compartment for inspecting dosing pumps and housing the electrical panel. The control panel is integrated into the plant and is equipped with a PLC for managing the entire purification system. The system works synergistically to control the entire purification process, including influent pump, chemical dosing, flocculant agitation and mixing. The initial chemical-physical treatment allows effective sedimentation through the lamellar packs located in the second compartment of the monoblock, adjacent to the chemical mixing tanks. The MBR modules are located in the third compartment, followed by all the planned filtration stages in the last compartment.

The structure is fabricated at our workshop using stainless steel AISI 304 sheets and tubular frames.

Advantages

- Operational flexibility in terms of purification capacity without a significant decrease in purification efficiency, even in the case of increased flow rates and/or pollutant loads.

- Simplicity of management.

- Minimal footprint.

- Easy removal and relocation to another site.

- Potential for expansion by adding one or more modules.

Options

Depending on specific needs and requests, various types of treatment can be carried out on each plant, such as:

- Internal and external galvanizing.

- Internal enameling and external painting.

Accessories

- Control Electrical Panel

- Mixers

- Dosing Pumps for Chemical Products Dosage

- Lamellar Packs

- MBR Modules (Membrane Bio-Reactor)

- Activated Carbon Filter

- Protection Modules for Ultrafiltration and Nanofiltration

- Reverse Osmosis

- UV Dechlorinato